Proper Rock drill lubrication is of critical importance to avoid frequent reliability problems and maintain operating cost at an acceptable level. Low lubrication lead to premature wear of bushings, failure of ball bearings and excessive wear of all rotative and sliding parts. Excess of lubrication, or water contamination of the oil leads to frequent failure of the piston striking face and corrosion that weaken the parts.

So we understand that the setting of the lubrication flow is very important as the control of the water content on the oil.

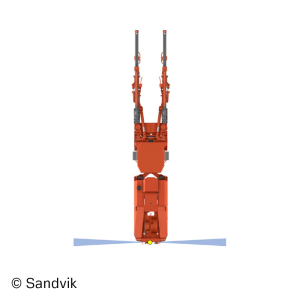

Some of the Sandvik drills are still operating on the field with KVL10-1 shank lubrication system. The function of this system is very basic (which can be considered an advantage) but it has two important critical flaws:

• It’s impossible to control accurately the oil flow.

• The water coming from the moisture on the air flow contaminate the oil in the tank (air flow and oil tank not separated).

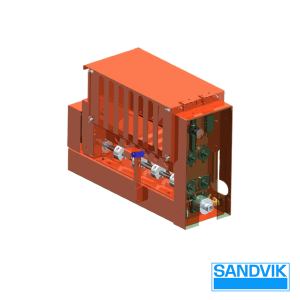

In order to limit rock drill failure generated by improper oil flow or water contamination of the lubrication oil, Sandvik offers to replace the KVL10-1 shank lubrication system by SLU-1.

SLU-1 shank lubrication system offers the possibility to adjust with great accuracy the oil flow. Also, the oil tank is separated from the air flow, which avoid water contamination of the oil in the tank.