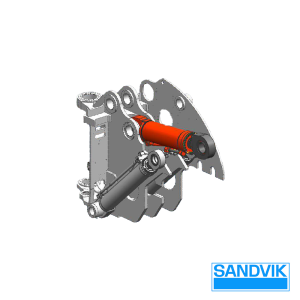

Working at height is one of the highest risk that mine workers are facing. And statistics show that slip and fall are a major cause of accident in the mining industry with several fatalities registered every year. On loaders, some maintenance and repair operations have to be done from the top deck. .To help our customers to control fall hazards during maintenance and repair operations, Sandvik has developed the Safety Rails system that offers an efficient protection against the risk of fall. The Safety Rails system is specifically designed for underground mining harsh environment. The Safety Rails system is operated by an electro-hydraulic system, providing immediate protection to the worker while climbing on the machine.

Safety rails for loaders

ADVANTAGES

-Safety Rails mitigate the risk that service people fall from the top of the machine.

-Foldable system that stays permanently on the machine, is always available, even if the machine is not located on the workshop.

-Simple and reliable system. Easy and quick to set-up.

CUSTOMER VALUES

-Improve the safety of the maintenance and repair operations

-Able to protect the people in any circumstances.

-Easy to use, require minimal training to be used. Minimal maintenance and withstands tough mining conditions.

-Immediate safety to the person climbing on top of the machine.

Category: Loaders

| Loaders | Sandvik LH307, Sandvik LH410, Sandvik LH514, Sandvik LH517, Sandvik LH517i, Sandvik LH621, Sandvik LH621i |

|---|---|

| Application area | Safety and environmental improvement |