KIT CONTENT

| QTY | PART NO. | PART DESCRIPTION |

| 1 | BC00003417 | Mako 50mm L/H Cast Corner Standard |

| 1 | BC00003418 | Mako 50mm R/H Cast Corner Standard |

| 7 | BC00003429 | Mako 50mm Weld on Boss |

| 1 | BU00081585 | Mako 50X2330X648 Plate Lip |

MAKO ADVANTAGES

• Straight and corner shrouds optimised for 1:1 wear life, eliminating the need for half-life change-outs of corners. (*) Subject to certain mining applications and conditions.

• 20-per cent lower top leg for enhanced material flow when dumping.

• Optimised design and materials increase wear life by 16 per cent over predecessor.

• Shroud width altered to optimise number required, reducing number of parts.

MAKO BENEFITS

• Even longer bucket service life

• Reduced maintenance frequency

• Improved safety during maintenance

• Reduced frequency of lip rebuilds

• Fewer parts to track

• Increased loader availability

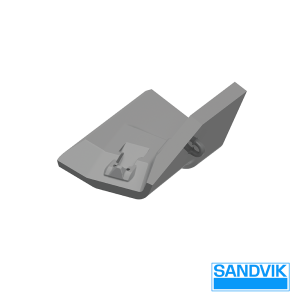

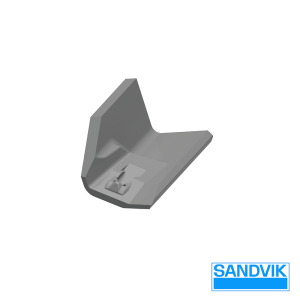

NEW COURNER SHROUDS DESIGN

When corner and straight shrouds wear at different rates, additional maintenance stops may be required for half-life change-outs of corners. The wear rate for MakoTM corners and straight shrouds has been optimised to close to 1:1, meaning fewer maintenance stops and greater uptime.

NEW CAST CORNERS

The corner is a high-stress zone on the bucket that faces an elevated risk of fatigue failure. Patented MakoTM cast corners have undergone structural improvements that make them resistant to fatigue, extending the life of the bucket lip.

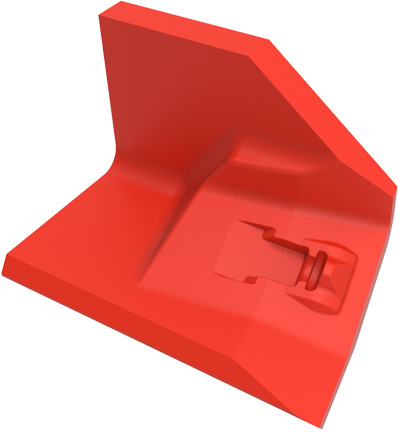

MAKO CHARACTERISTICS

• Constructed from Sandvik SS5000 steel alloy for increased hardness and added mechanical strength.

• Single cartridge locking-and-removal system.

• Structurally improved cast corners.

• Innovative shroud lifting device for safer workshops.

• Top and bottom wear indicators for ease of inspection.