Sandvik DD422i And DD422iE face drills have introduced major improvements compare to the previous generation of drills. Particularly concerning the operator safety and usability with the new cabin design that brings drastically reduced noise levels, improved drilling visibility and the possibility to drill seated. Drilling performance and costs of drilling consumables are also greatly improved thanks to the torque optimized drilling control (approximately 10% improvement in productivity and nearly 20% improvement on drill consumable costs measured during field test, compare to previous generation hydraulic controlled jumbo).

In order to make these benefits available for ground support application, Sandvik has recently released a new Dual Controls package. This package is retrofitable on active DD422i and DD422iE.

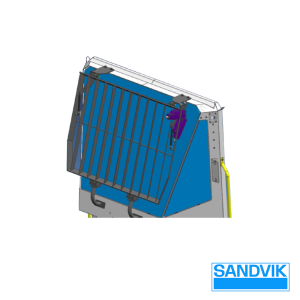

Dual Drilling Controls improve fleet optimisation, versatility and performance for the Sandvik DD422i and Sandvik DD422iE face drills. The Dual Controls package was designed to address a wide range of needs identified by mining contractors currently using development drills for a variety of tasks including boring, bolting and meshing DD422i and DD422iE Dual Controls (DC) allows customer to use a single platform for all drilling applications.

Depending original machine configuration, the retrofit kit could require complete new cabin with Dual Drilling Controls, TFX feeds, hydraulic parallelism booms with hosing, electric system modification and software update,

Retrofit of Dual Drilling controls imply the removal of boom instrumentation and drilling automation.