Flushing is needed on a drill rig for removing the cutting generated by the drill bits. A proper removal of cuttings is one key parameter for maximized drilling performance, rock drill reliability and optimized rock tool life.

The standard media used for flushing holes on Underground drills is water. But sometime, rock condition do not allow the use of water flushing (hole collapse after being drilled, avoiding to charge it with explosive). Also, In some locations, water can also be a rare and expansive resource that cannot be wasted.

To solve this issue, Sandvik has developed Air Mist Flushing system for Underground Drills.

The Air Mist Flushing use mainly compressed air for flushing but with the injection of a small quantity of water to avoid generation of dust that could be harmful for the mine personal and generate high cost of ventilation.

The pressurized water is conveyed through a special jet that sprays it into the air from inside a special Y connection. This connection is located as close as possible from the rock drill / rotary drill flushing head in order for the sprayed water not to settled down in the line.

Depending on unit model supply of air can be done internally (with replacing the original compressor by a bigger one or addition of a second compressor, or addition of air receiver(s)).

Also in few models, a water tank and OA cooler can be installed to have on-board (internal) water supply.

OFFERING

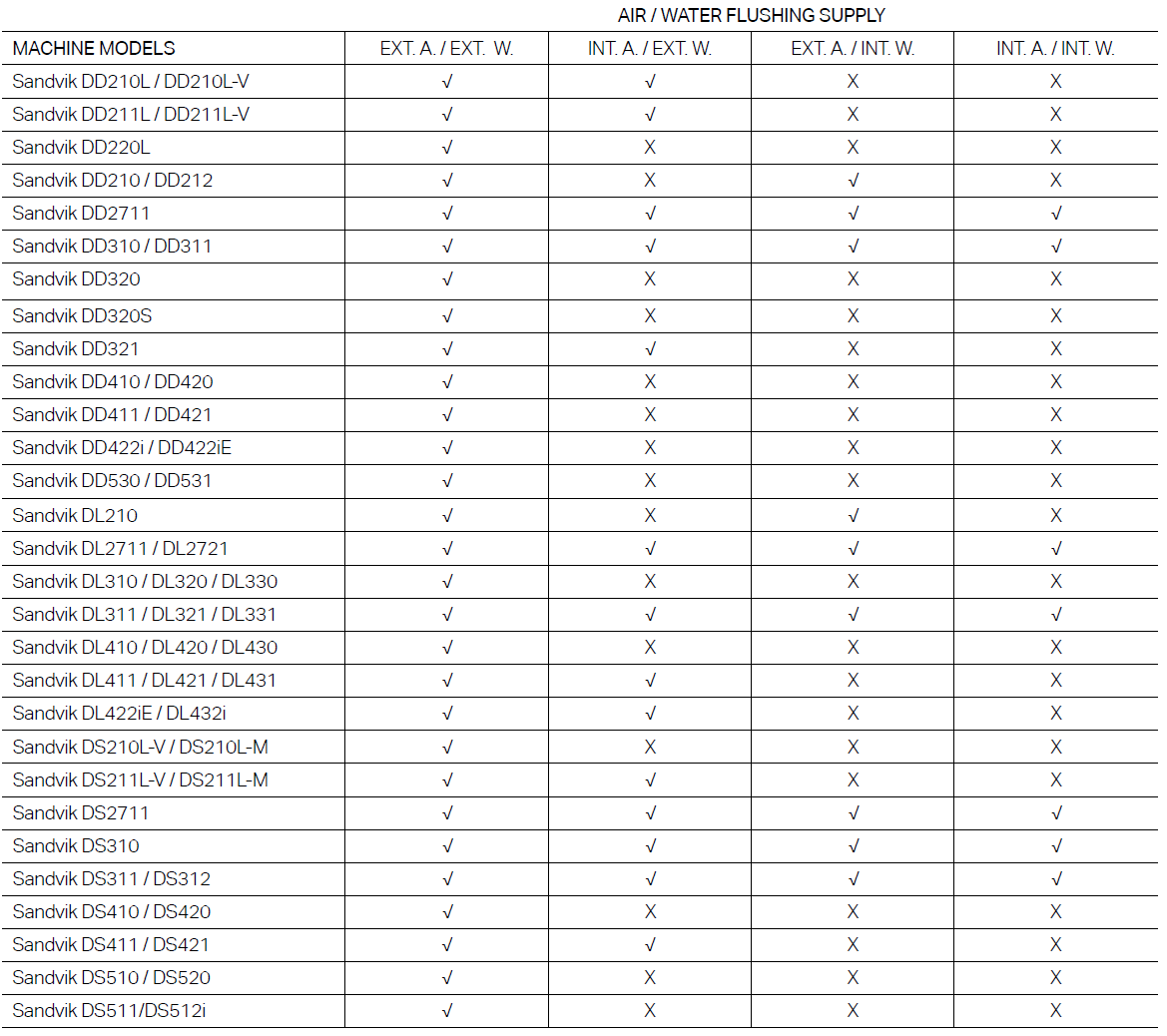

The Air Mist Flushing Upgrade Solution is available for the following UG Drills models*:

*Possibilities of implementing different configurations of the Air Mist Flushing can vary according machine specifications and options. Please contact your local Sandvik Representative for more information.